In order to complete the modeling quickly and effectively, the following procedure is possible.

In the example, a simple lug is modeled. The start of this lug was a surface with two holes; this surface (also without openings) is copied.

If you select both surfaces, you can right-click to select the "Create solid with contact ..." option. Finally, the contact volume is converted into a regular volume with, for example, isotropic material behavior. Double-click the solid to open the volume dialog box where you can change the type to "Material".

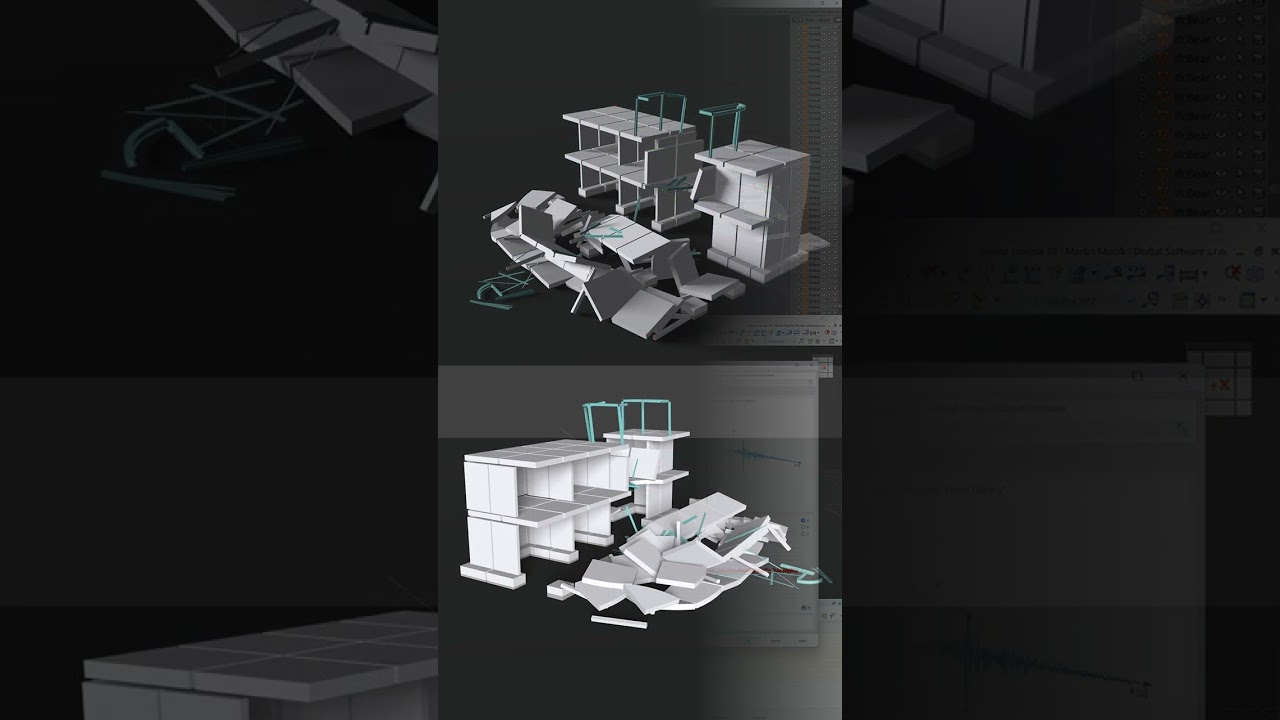

The complete procedure is shown again in the corresponding video

![Reduction of Building to Cantilever Structure: The individual mass points represent the floors. The deflection due to the normal compression forces shown in (a) is (b) converted into equivalent moments of displacement or shear forces [2].](/en/webimage/009762/2420261/01-en-png-12-png.png?mw=350&hash=dd36dc43123116724231958668ad6cdcb13a0169)

.png?mw=512&hash=ea9bf0ab53a4fb0da5c4ed81d32d53360ab2820c)

.jpg?mw=350&hash=8f312d6c75a747d88bf9d0f5b1038595900b96c1)